Contact Number:15980782353

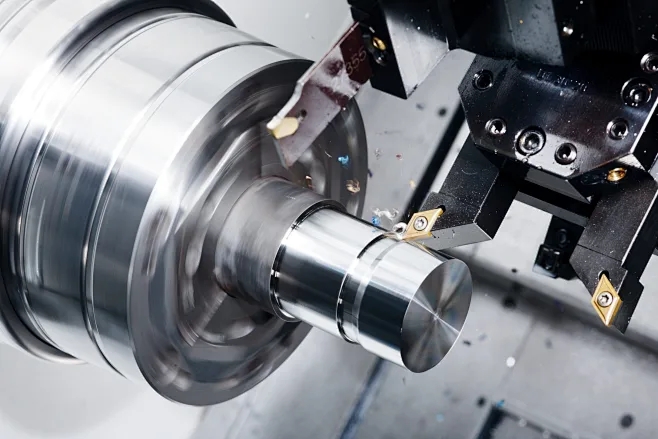

The advantages of five axis machining

There are at least five coordinate axes (three linear coordinates and two rotational coordinates) on a machine tool, and they can coordinate their movements simultaneously for machining under the control of a computer numerical control (CNC) system. It was first applied in military industries such as aerospace and shipbuilding, and later in industries such as automobiles and molds, gradually developing towards "civilian" development. Internationally, five axis machining technology is regarded as a symbol of a country's industrialization level.

Only one clamping is needed to complete all or most of the processing of complex parts - improving the quality and efficiency of processing. The processing of some complex shaped parts can only be achieved by using five axis processing - expanding the process range to adapt to the new direction of CNC machine tool development - compounding. Five axis machining has a wide range of applications. Parts with complex shapes and poor opening of machining channels have complex curved surfaces and large machining surface areas, requiring high cutting efficiency. Three axis machining can be used for parts, but considering certain factors, five axis machining is sometimes proposed.